Peb ua dab tsi

Lub Hnub Qub Machining Technology yog lub chaw tsim khoom lag luam pwm, tshwj xeeb hauv cov pwm loj thiab complex molding, peb muab cov tshuaj pwm ib leeg, uas suav nrog cov pwm pwm tsim, pwm tsim, pwm fabrication, yas los yog casting tivthaiv tsim thiab cov kev pabcuam thib ob.

Ntawm Star Machining Technology, peb muaj kev paub tob ntawm kev tsim thiab qhia txog kev tsim cov txhuas tuag casting pwm thiab txhaj tshuaj pwm.Peb pib ua pwm ua ntej los ntawm kev ua hauj lwm nrog koj los txiav txim qhov tsim-muaj peev xwm ntawm tus tsim.Peb kuj tseem yuav pab tsim cov qauv kev ua tau zoo rau qhov ua tiav.Qhov kev koom tes ua ntej no nyob rau hauv qhov tuag casting pwm tsim thiab kev soj ntsuam txheej txheem pab kom cov khoom zoo.Peb tuaj yeem tsim cov qauv tsim kom ntxaws, cov ntawv luam tawm thiab cov lus qhia tshwj xeeb los ntawm koj tus qauv, lossis koj cov ntaub ntawv 2D lossis 3D CAD.Peb cov kws tsim pwm tsim tau muab rau koj qhov zoo tshaj plaws ntawm ob lub ntiaj teb: ua cov txheej txheem thiab cov khoom siv hauv tes ntawm cov kws txawj thiab cov kws paub txog kev txawj ntse.Peb cov pwm tsim thiab precision tsim muaj peev xwm txhais tau rau hauv kev tsim khoom uas tsim cov khoom ntawm cov khoom zoo.Thaum koj commission Star Machining Technology los tsim koj cov pwm, koj tau paub tseeb ntawm qhov chaw nrog kev ua tau zoo ib yam thiab siab tshaj plaws rov qab los ntawm koj cov cuab yeej peev.

Peb kuj nkag siab tias qhov tshwj xeeb tshaj plaws, nruj-toleranced qhov chaw, nrog lub sij hawm ua nruj heev, yuav tsum tau siv cov cuab yeej zoo tshaj plaws - los ntawm thawj cov khoom lag luam los ntawm lub neej ntawm koj cov khoom.Txawm hais tias peb tab tom tsim pwm rau ib qho qauv los yog ntau kab noj hniav, tag nrho cov kab ntau lawm pwm, tshwj xeeb cov cuab yeej yog nyob rau hauv plawv ntawm Star Machining Technology tuag casting molding thiab txhaj tshuaj molding lag luam.

Peb cov peev txheej engineering suav nrog:

Tshooj Tsim:Peb tsim cov khoom uas ua rau cov cuab yeej siv tau zoo tshaj plaws

Flow Analysis:Peb ua cov yas yaj ntws tsom xam nrog Moldex3D

Pwm Tsim:Tag nrho cov qauv tsim yog tsim los ntawm Creo Parametric

Kev Tshawb Fawb & Cov Qauv:Peb tuav ib lub tsev qiv ntawv ntawm tus neeg siv khoom tus qauv

Kev Qhia Txog Kev Txhim Kho:Cov kab kos thiab cov kev hloov tshiab tsis tu ncua tau muaj

Electronic Data Transfer:FTP thiab email attachments muaj

Khaws thiab hloov kho CAD

Hom Pwm Peb muab

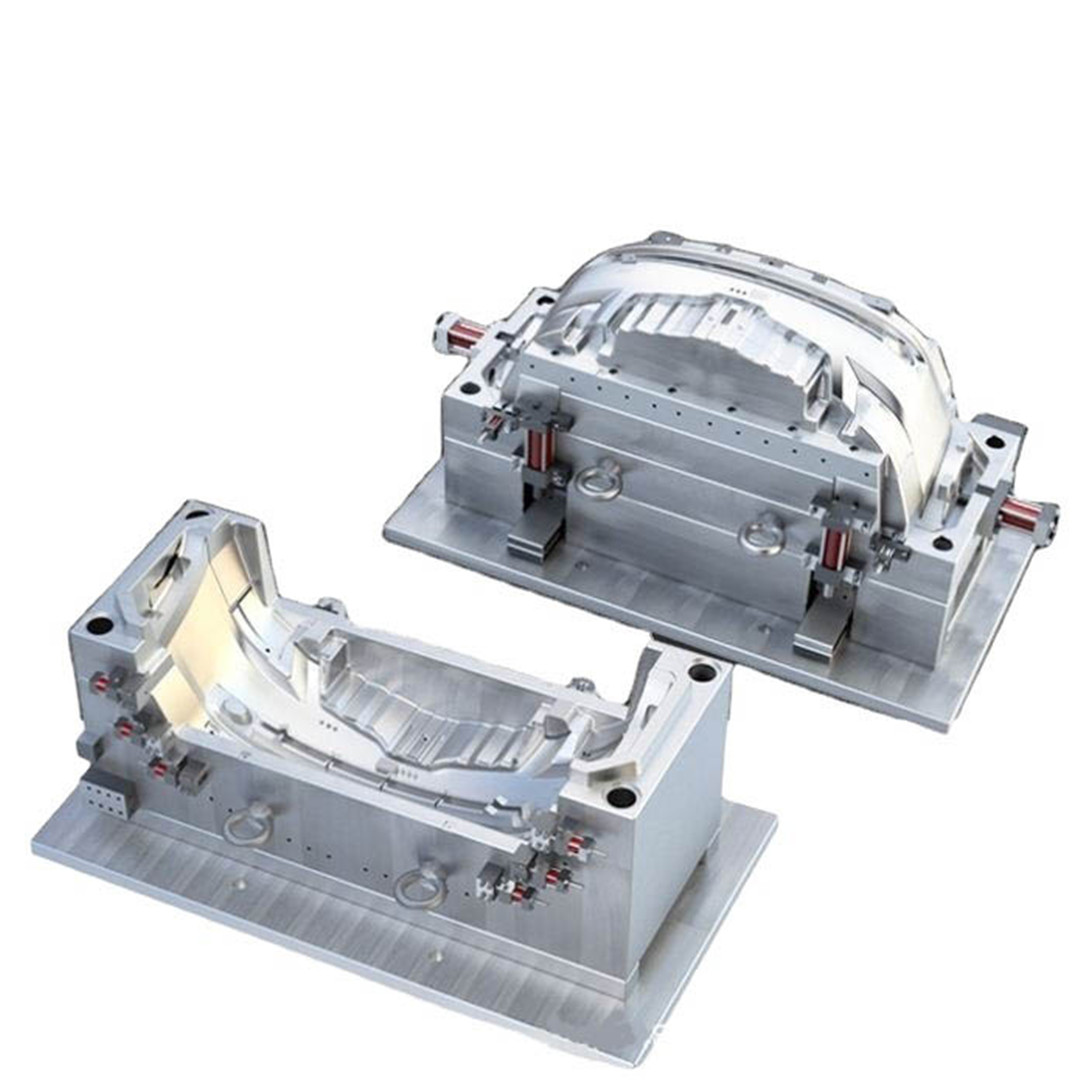

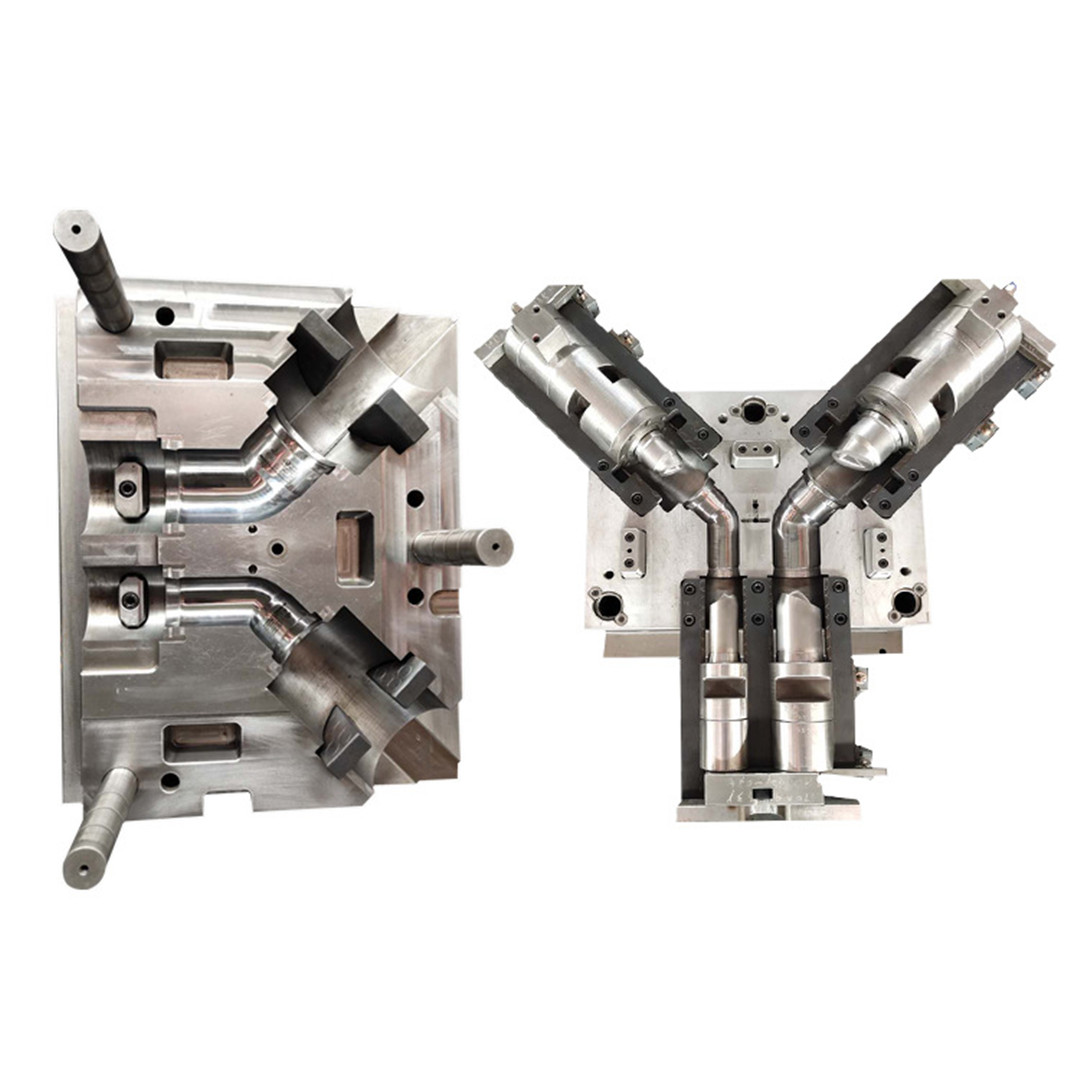

Tuag Casting Pwm

Tsis zoo li ntau tus kws tshaj lij prototyping, peb tuaj yeem muab cov hlau casting pwm (thiab cov kev pabcuam qis qis los ntawm peb cov neeg koom tes).Cov pwm no - feem ntau yog ua los ntawm cov hlau tawv - tuaj yeem siv los ua cov khoom ntawm txhuas, zinc, magnesium thiab lwm yam hlau tsis muaj hlau.

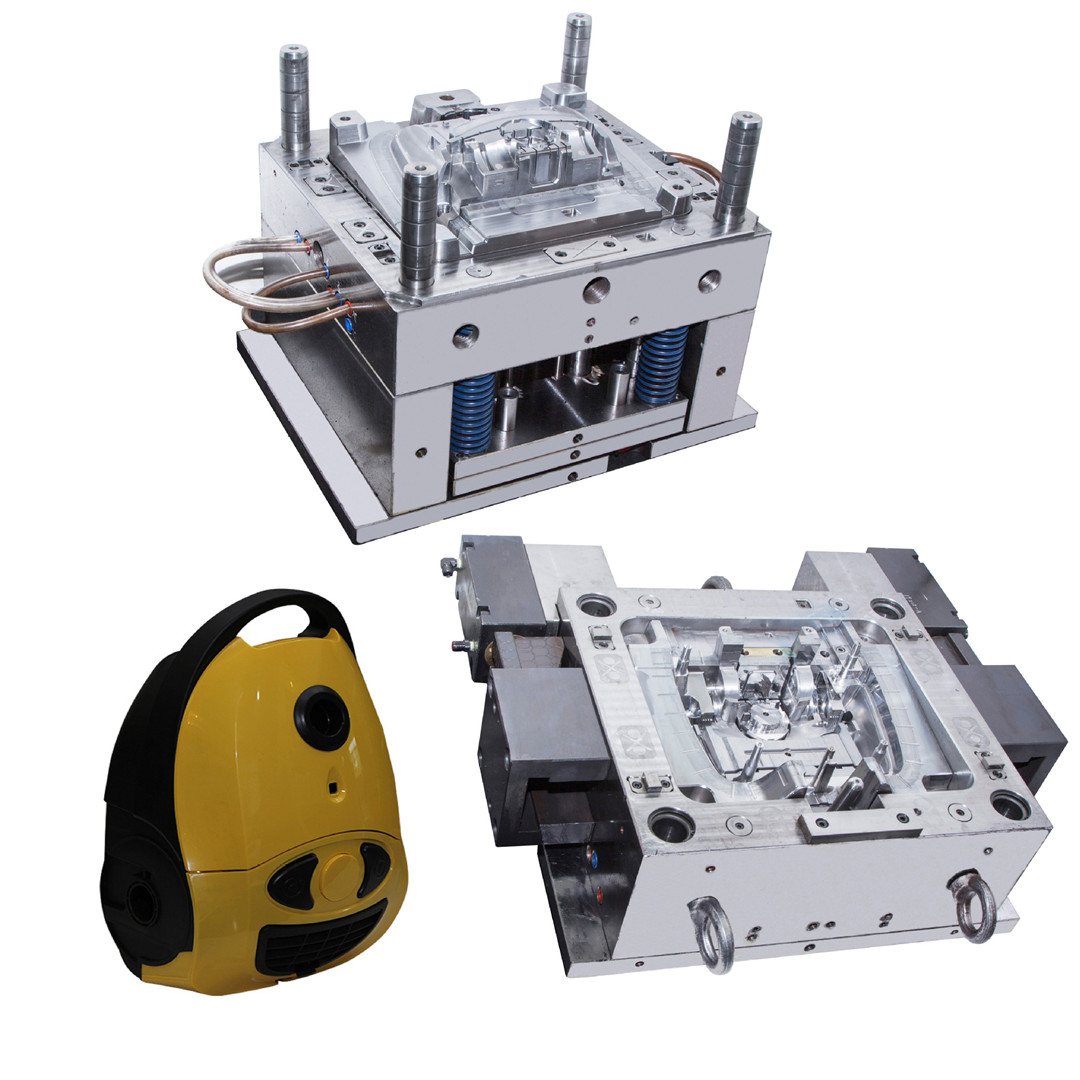

Yas Txhaj Pwm

Cov yas txhaj tshuaj pwm yog txhuas lossis hlau pwm siv los ua cov khoom los ntawm ntau yam yas, nrog rau cov nylons, acrylics, elastomers thiab cov khoom siv ntxiv xws li iav-filled polyamide.Kev cai yas pwm tuaj yeem nyob nruab nrab ntawm 10,000 thiab 1,000,000 txhaj tshuaj.

Cov txheej txheem ua pwm

Kev tsim pwm yog txheej txheem nyuaj uas yuav tsum muaj kev txawj ntse thiab kev paub dhau los.Txawm hais tias txhua rooj plaub sib txawv, ib qho kev txiav txim rau ib txheej pwm tuaj yeem mus rau qee yam zoo li no:

1. DFM

Thaum tus neeg siv khoom lees paub qhov kev txiav txim ntawm cov pwm, peb yuav pib ua qhov kev ntsuam xyuas thawj zaug ntawm cov khoom kom tau txais lub tswv yim ntawm cov kab, rooj vag txoj haujlwm, thiab lwm yam.

2. Pwm tsim thiab pwm ntws tsom xam

Cov kauj ruam thib ob suav nrog kev siv qhov kev twv ua qauv software uas tso cai rau peb pom tias cov khoom siv molten yuav coj li cas thaum nws nkag mus rau hauv pwm, tso cai rau kev txhim kho ntxiv rau kev tsim.

3. CNC machining thiab EDM

Peb ua cov pwm thawj zaug siv cov cuab yeej zoo machining, nrog rau cov yas, hlau, txhuas, thiab lwm yam xaiv los ntawm cov neeg siv khoom.

4. T1 qauv

Nrog cov pwm tsim tshiab, peb ua tus qauv T1 kom muaj lub zeem muag pom tseeb ntawm cov neeg siv khoom qhov kawg pwm yuav tig tawm li cas.

5. Kev txhim kho yog tias tsim nyog

Raws li peb qhov kev soj ntsuam ntawm tus qauv T1, peb tshuaj xyuas cov pwm tsim thiab ua txhua yam kev hloov kho uas xav tau.

6. Pib ntau lawm thiab shipping

Peb tsim cov pwm raws li qhov kawg specifications ua ntej xa lawv mus rau cov neeg siv khoom.