Txhaj Molding yog dab tsi?

Txhaj tshuaj molding yog txheej txheem kev siv pwm.Cov ntaub ntawv xws li hluavtaws resins (yas) yog rhuab thiab melted, thiab ces xa mus rau pwm qhov chaw uas lawv tau txias los tsim cov qauv tsim.Vim qhov zoo ib yam li cov txheej txheem ntawm kev txhaj tshuaj los ntawm kev txhaj tshuaj, cov txheej txheem no hu ua txhaj tshuaj molding.Qhov kev khiav ntawm cov txheej txheem yog raws li nram no: cov ntaub ntawv yog melted thiab poured rau hauv pwm, qhov twg lawv harden, thiab ces cov khoom raug muab tshem tawm thiab ua tiav.Nrog rau kev txhaj tshuaj molding, ntau qhov sib txawv, nrog rau cov uas muaj cov duab nyuaj, tuaj yeem ua haujlwm tsis tu ncua thiab sai sai hauv cov ntim loj.Yog li ntawd, kev txhaj tshuaj molding yog siv los tsim cov khoom lag luam thiab cov khoom lag luam hauv ntau qhov kev lag luam.

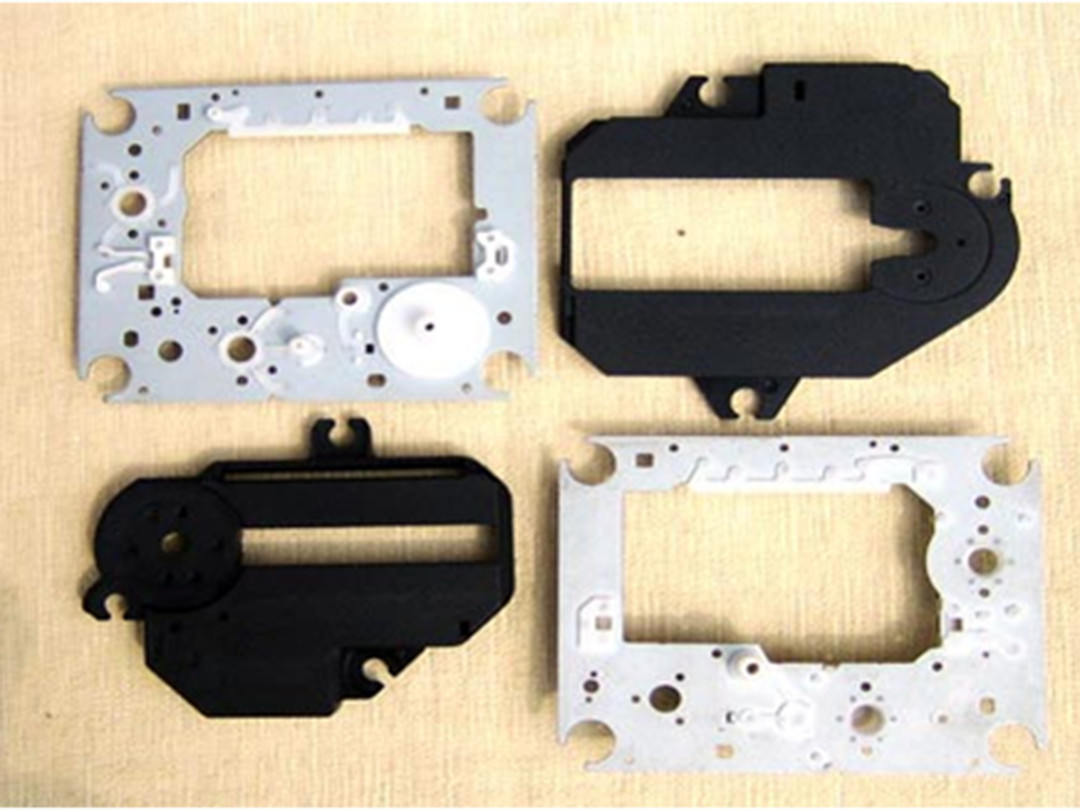

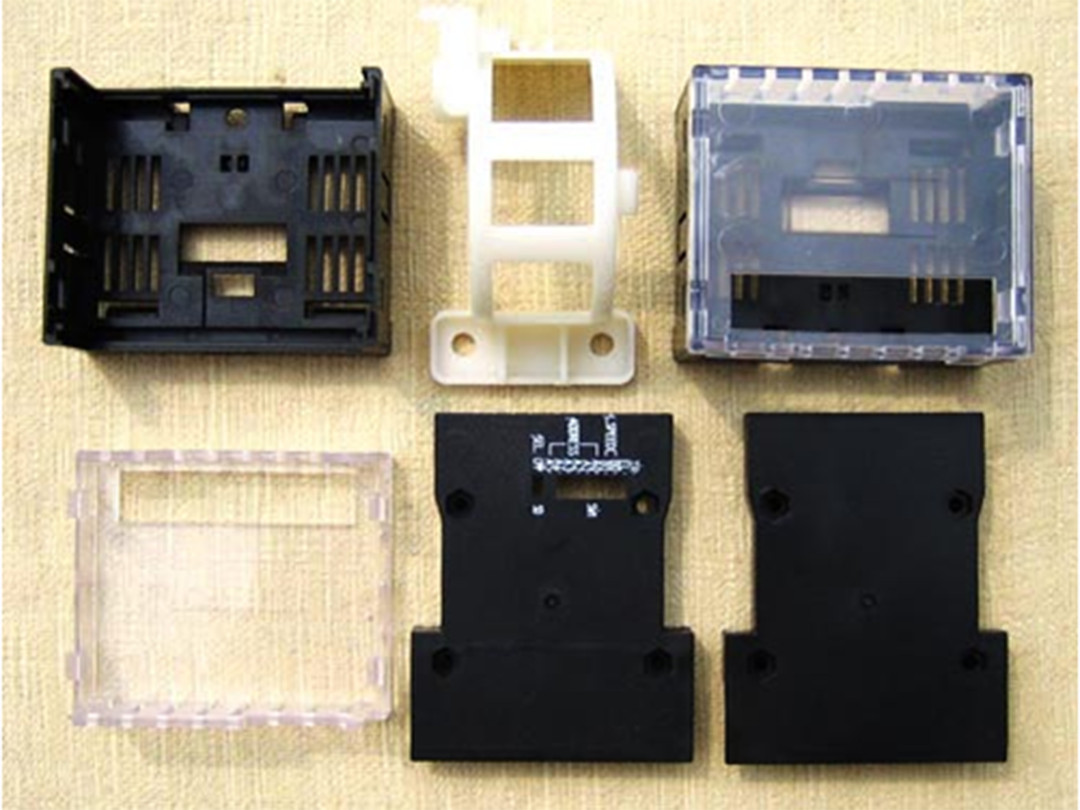

Kev txhaj tshuaj molding yog siv los tsim ntau yam xws li hlau spools, ntim, lub hau lub raj mis, cov khoom siv tsheb thiab cov khoom ua si, cov khoom ua si, hnab tshos, qee cov khoom siv suab paj nruag, ib lub rooj zaum thiab cov rooj me me, cov thawv ntim khoom, cov khoom siv kho tshuab, thiab lwm yam yas. cov khoom muaj hnub no.Txhaj tshuaj molding yog cov txheej txheem niaj hnub tshaj plaws ntawm kev tsim cov khoom yas;nws yog qhov zoo tagnrho rau kev tsim cov ntim siab ntawm tib yam khoom.

Kev Txhaj Tshuaj Molding Ua Haujlwm Li Cas?

Lub Hnub Qub Machining muab cov kev daws teeb meem ua tiav uas suav nrog txhua yam ntawm cov ntaub ntawv pov thawj, kev tsim cov cuab yeej, ib feem fabrication, xov, thiab kev soj ntsuam zaum kawg.Peb pab neeg ntawm kev tsim cov kws tshaj lij tau cog lus los muab koj cov kev pabcuam siab tshaj plaws rau kev txhaj tshuaj yas molding cov kev pabcuam ntawm txhua qhov loj lossis qhov nyuaj.

Feem ntau txhaj tshuaj molding tuaj yeem muab faib ua cov kauj ruam hauv qab no:

1. Txheej txheem tsom xam ntawm cov khoom yas:

Ua ntej kev tsim pwm, tus tsim qauv yuav tsum ua tib zoo tshuaj xyuas thiab kawm seb cov khoom yas puas ua raws li txoj cai ntawm kev txhaj tshuaj molding, thiab yuav tsum tau sib tham nrog tus tsim khoom kom zoo, thiab kev pom zoo tau mus txog.Nrog rau cov duab geometric, qhov tseeb qhov tseeb thiab qhov xav tau ntawm cov khoom, kev sib tham tsim nyog, sim kom tsis txhob muaj qhov nyuaj ntawm kev tsim pwm.

2. Pwm qauv tsim.

3. Txiav txim siab cov khoom pwm thiab xaiv cov khoom txheem.

Hauv kev xaiv cov khoom siv pwm, ntxiv rau kev txiav txim siab qhov tseeb thiab qhov zoo ntawm cov khoom, kev xaiv raug yuav tsum tau ua nrog rau kev ua tiav thiab kev kho cua sov ntawm lub Hoobkas pwm.Tsis tas li ntawd, txhawm rau ua kom luv luv lub voj voog tsim khoom, siv cov txheej txheem uas twb muaj lawm ntau li ntau tau.

4. Yam khoom ua thiab pwm los ua ke.

5. sim cov pwm.

Ib txheej pwm tsuas yog ua tiav 70% mus rau 80% ntawm tag nrho cov txheej txheem tsim los ntawm kev pib tsim mus rau kev ua tiav ntawm kev sib dhos.Qhov yuam kev tshwm sim los ntawm qhov tsis sib xws ntawm qhov kev txiav txim siab ntawm qhov shrinkage thiab qhov tseeb shrinkage, smoothness ntawm demolding, thiab cov nyhuv txias, tshwj xeeb tshaj yog cov cawv ntawm qhov loj, txoj hauj lwm, thiab cov duab ntawm lub rooj vag ntawm qhov tseeb thiab cov tsos ntawm cov khoom, yuav tsum yog. kuaj los ntawm kev sim pwm.Yog li, kev sim pwm yog ib kauj ruam tseem ceeb los xyuas seb cov pwm puas tsim nyog thiab xaiv cov txheej txheem molding zoo tshaj plaws.

Txhaj Molding Applicons

Kev txhaj tshuaj molding yog siv los ua cov duab puab ntawm ntau qhov ntau thiab tsawg uas muaj cov phab ntsa tuab.Yam khoom xws li khob, ntim, cov khoom ua si, cov kav dej phwj, cov khoom siv hluav taws xob, cov xov tooj txais, lub raj mis, cov khoom siv tsheb thiab cov khoom siv.

Khoom noj khoom haus thiab dej haus kev lag luam

Thaum nws los txog rau kev txhaj tshuaj molding, kev lag luam zaub mov thiab dej haus tso siab rau cov ntaub ntawv yas los tsim cov khoom ntim thiab ntim khoom.Txij li qhov kev lag luam no yuav tsum ua raws li kev cai huv huv thiab kev nyab xeeb, kev txhaj tshuaj yas molding yog qhov tsim nyog los xyuas kom meej ntau yam kev ua tiav, suav nrog BPA-dawb, FDA-certified, non-toxic thiab GMA-safe cov cai.Los ntawm cov khoom me me li lub kaus mom lub raj mis mus rau cov tais uas siv hauv TV noj hmo, kev txhaj tshuaj molding muab ib qho chaw nres tsheb rau tag nrho cov khoom noj thiab dej haus kev lag luam ntim thiab ntim khoom xav tau.

Automotive Manufacturing

Kev lag luam tsheb niaj hnub no yuav ua rau txo lub cev hnyav raws li qhov kev ntsuas tseem ceeb kom txuag tau lub zog.Internationally, tus nqi ntawm engineering plastics hauv tsheb tau raug suav tias yog ib qho tseem ceeb ntsuas ntsuas qib ntawm lub teb chaws kev lag luam tsheb.Nws cia siab tias qhov kev loj hlob ntawm cov tsheb yas yuav yog 10-20% yav tom ntej.Tam sim no, tus nqi ntawm cov yas siv nyob rau hauv domestic tsheb tsuas yog 5-6% ntawm lub tsheb hnyav.Tam sim no, Tuam Tshoj txoj kev lag luam tsheb tsim tau nce xyoo los ntawm xyoo.Nws tseem yuav nce ntxiv txhua xyoo nyob rau yav tom ntej.Feem ntau ntawm cov khoom siv yas siv hauv tsheb yog txhaj tshuaj molded qhov chaw, xws li pem hauv ntej thiab nram qab bumpers, pem hauv ntej thiab nram qab panels, ntsuas vaj huam sib luag thiab lawv accessories, kauj log thiab lawv accessories, radiator grilles, ntau kab, thiab xim ua ke teeb ntxoov.

Txhaj tshuaj molding yog ib txoj kev tsim khoom tsim nyob rau hauv uas automotive moldmakers txhaj molten yas khoom rau hauv pwm kab noj hniav.Cov yas molten ces txias thiab hardens, thiab cov chaw tsim khoom rho tawm cov khoom tiav.Txawm hais tias cov txheej txheem tsim pwm yog qhov tseem ceeb thiab nyuaj (ib qho pwm tsim tsis zoo tuaj yeem ua rau muaj qhov tsis xws luag), kev txhaj tshuaj molding nws tus kheej yog ib txoj kev txhim khu kev qha ntawm kev tsim cov khoom yas nrog cov khoom zoo.

Khoom Siv Hauv Tsev / Txuag Zog

Xim TVs, tub yees, rhaub dej, tshuab ntxhua khaub ncaws, roj teeb, hnub ci hnub ci, daim phiaj hnub ci, khib nyiab cais lub thawv, cov rooj sab nraum zoov thiab cov rooj zaum, rooj tog zaum, cov tais yas loj thiab cov thawv ntim khoom, thiab lwm yam. Cov khoom no tuaj rau hauv zej zog, ntsib kev tiv thaiv ib puag ncig. , ntsib kev txuag hluav taws xob, thiab muaj qhov xav tau loj heev rau kev txhaj tshuaj molding khoom.Nws yog ib qho tsim nyog los muab cov tshuab txhaj tshuaj molding tshuab nrog kev ua tau zoo thiab tus nqi sib piv, cov txheej txheem ua npuas dej txhaj tshuaj molding tshuab, microcellular ua npuas ncauj txhaj tshuaj molding tshuab, thiab ntau txheej txheej txhaj tshuaj molding tshuab.

Cov cuab yeej siv hluav taws xob, IT, kev kho mob thiab cov khoom ua si ntse

Qhov no yog ib qho kev lag luam xav tau loj loj los ntawm cov tshuab me me thiab micro txhaj molding tshuab.Hauv daim teb no, ntau lub tshuab txhaj tshuaj molding tau nkag mus rau hauv tsev neeg, feem ntau ua ntau yam haujlwm ntawm lub cev muaj zog, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob, cov khoom sib txuas, cov hloov pauv, cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob sib xyaw ua ke, universal lub koob yees duab, lub koob yees duab instrumentation Cheebtsam, kev kho mob precision Cheebtsam. thiab zoo ceramic Cheebtsam.

Infrastructure tsim kev lag luam xav tau

Txoj kev loj hlob ntawm tib neeg yog sib cais los ntawm kev tsim kho vaj tse, thiab qhov tseem ceeb tshaj plaws ntawm kev tsim kho vaj tse yog kev tsim cov kav dej.Kev ua lag luam muaj peev xwm ntawm ntau yam kev txhaj tshuaj molded yeeb nkab fittings thiab accessories muaj feem xyuam rau kev tsim kho, kev siv dej, kev txuag dej, kev sib txuas lus, cables thiab kav dej yog loj heev.Qhov nruab nrab txhua xyoo kev loj hlob ntawm cov kav dej hauv kuv lub tebchaws yog 20%.Los ntawm 2025, cov kav dej yas yuav suav txog 50% ntawm tag nrho cov kav dej, thiab cov kav dej nruab nrab thiab qis hauv nroog yuav ncav cuag 60%.Yog tias qhov kev thov txhua xyoo rau cov kav dej yas yog 80,000 txog 100,000 tons raws li 50% ntawm cov kav dej yas, nws tuaj yeem suav tau tias qhov kev thov rau cov yeeb nkab loj loj fittings lag luam, thiab feem ntau cov tshuab txhaj tshuaj molding tsuas tuaj yeem tsim kev txhaj tshuaj molding ntawm UPVC thiab PE. hauv qab 250-300mm.Cov yeeb nkab fittings.

Vim li cas thiaj xaiv Star Machining rau Yas Txhaj Molding

Cov cuab yeej pwm tsim khoom zoo tshaj plaws pib nrog cov ntaub ntawv zoo, tswj cov txheej txheem nruj, thiab cov kws tshaj lij cov cuab yeej.Tsuas yog ib tus neeg muag khoom uas muaj kev paub ntau xyoo txhawb nqa Fortune 500 tuam txhab tuaj yeem ua kom rov ua tau zoo dua rau koj cov kev xav tau ntau lawm.Nov yog qee qhov zoo uas Star Machining muaj rau cov cuab yeej tsim khoom tsim thiab kev txhaj tshuaj molding.

Ua tiav Kev Pabcuam

Peb muaj ntau tshaj li cov cuab yeej ua thiab molding kev pab.Peb cov pob tiav suav nrog txhua txheej txheem tsim khoom uas koj xav tau rau tag nrho cov khoom tsim kho.

Ua pov thawj tiav

Ntau txhiab lub tuam txhab ntawm txhua qhov loj los ntawm thoob plaws ntiaj teb tau xaiv los ua haujlwm nrog Star Rapid los pab lawv tsim cov cuab yeej txhaj tshuaj pwm tshiab thiab cov khoom tiav.Koj txoj kev vam meej yog lub hauv paus ntawm peb lub koob npe nrov.

Kev txheeb xyuas cov khoom zoo

Koj txoj cai ua raws cai thiab koj txoj kev thaj yeeb nyab xeeb tau lees paub nrog peb lub tuam txhab kev lag luam-ua cov ntaub ntawv txheeb xyuas qhov zoo.Cov neeg ntseeg Star Rapid thaum txoj haujlwm tiag tiag yuav tsum yog.

Kev tsim kho kom zoo

Kev tsim qauv zoo rau kev tshuaj xyuas kev tsim khoom tuaj nrog txhua qhov cuab yeej thiab cov khoom tsim tsim.Koj yuav tau txais txiaj ntsig zoo dua thaum txuag sijhawm thiab nyiaj txiag.

Kev txawj ntse Quotations rau txhua qhov project

Peb txhawb koj lub hom phiaj kev loj hlob los ntawm tsis muaj qhov tsawg kawg nkaus xaj ntim lossis tus nqi rau peb cov tshuaj molding ntau lawm.Tsis tas li ntawd, peb muaj tus tswv AI quoting algorithm uas muab tus nqi nrawm, raug, thiab pob tshab ntawm txhua qhov project, txhua lub sijhawm.

Saib peb cov piv txwv rau kev txhaj tshuaj molding