CNC Machining yog dab tsi?

CNC machining yog cov txheej txheem tsim khoom uas siv computerized tswj los khiav lag luam thiab tswj cov tshuab thiab txiav cov cuab yeej los tsim cov khoom lag luam - xws li hlau, yas, ntoo, ua npuas ncauj, sib xyaw, thiab lwm yam.Thaum cov txheej txheem CNC machining muaj ntau lub peev xwm thiab kev ua haujlwm, cov ntsiab lus tseem ceeb ntawm cov txheej txheem tseem zoo ib yam thoob plaws txhua qhov ntawm lawv.

CNC machining txheej txheem yog tsim rau ntau yam industires, xws li automotive, aerospace, kev tsim kho, thiab kev ua liaj ua teb, thiab muaj peev xwm tsim tau ib tug ntau yam ntawm cov khoom, xws li autombile thav duab, cov cuab yeej phais, lub dav hlau cav, zog thiab hais txog.Cov txheej txheem encompasses serveral sib txawv computer-tswj machining kev khiav hauj lwm-xws li txhua yam, tshuaj, hluav taws xob thiab thermal txheej txheem-uas tshem tawm cov tsim nyog meter los ntawm lub workpiece los tsim ib tug kev cai-tsim ib feem los yog cov khoom.

CNC Machining ua haujlwm li cas?

Lub hauv paus CNC machining txheej txheem suav nrog cov theem hauv qab no:

Tsim qauv CAD

Hloov cov ntaub ntawv CAD rau CNC program

Npaj lub tshuab CNC

Ua haujlwm machining

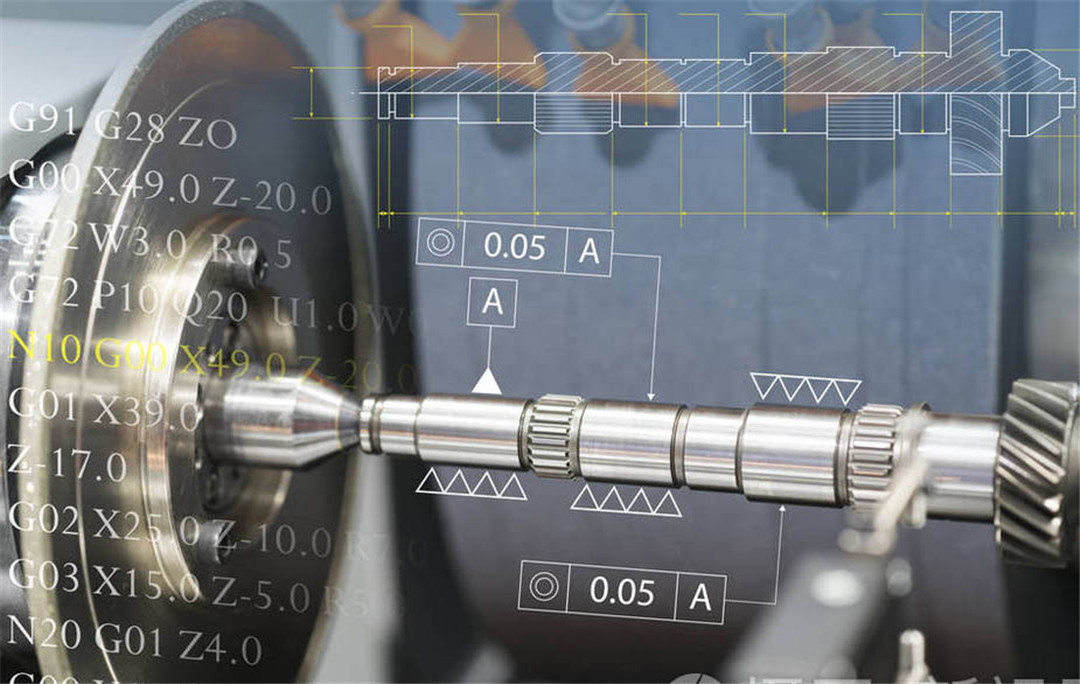

Thaum lub tshuab CNC ua haujlwm, cov kev txiav uas xav tau yog programmed rau hauv software thiab hais rau cov cuab yeej siv thiab cov tshuab, uas ua tiav cov dej num raws li tau teev tseg, zoo li tus neeg hlau.Nyob rau hauv CNC programming, lub code generator nyob rau hauv tus lej system feem ntau yuav xav tias mechanisms yog flawless, txawm tias muaj kev ua yuam kev, uas yog ntau dua thaum twg lub tshuab CNC raug qhia kom txiav ntau tshaj ib qho kev taw qhia ib txhij.Qhov kev tso kawm ntawm ib lub cuab yeej nyob rau hauv ib tug lej tswj system yog qhia los ntawm ib tug series ntawm inputs hu ua ib feem program.

Nrog lub tshuab tswj tus lej, cov kev pab cuam tau nkag los ntawm daim npav punch.Los ntawm qhov sib txawv, cov kev pab cuam rau CNC tshuab yog pub rau cov computers los ntawm cov keyboards me.CNC programming tau khaws cia rau hauv lub computer lub cim xeeb.Cov cai nws tus kheej yog sau thiab kho los ntawm programmers.Yog li ntawd, CNC tshuab muab kev nthuav dav ntau lub peev xwm.Qhov zoo tshaj plaws, CNC tshuab yog tsis muaj qhov zoo li qub vim tias cov lus qhia tshiab tuaj yeem muab ntxiv rau cov kev pab cuam ua ntej los ntawm kev hloov kho code.

Hom CNC Machining Operations CNC Tig

CNC Tig yog txheej txheem machining uas siv cov cuab yeej txiav ib leeg kom tshem tawm cov khoom los ntawm kev sib hloov ua haujlwm.Kev ua haujlwm muaj peev xwm ntawm cov txheej txheem tig muaj xws li tho txawv, tig ntsej muag, grooving, thiab xov txiav.Nyob rau hauv lub tshuab dhos tshuab, tej daim yog txiav nyob rau hauv ib ncig kev taw qhia nrog indexable cov cuab yeej.Nrog CNC thev naus laus zis, kev txiav ua haujlwm los ntawm cov tshuab dhos yog ua tiav nrog qhov tseeb thiab nrawm nrawm.CNC lathes yog siv los tsim cov qauv tsim uas tsis tuaj yeem ua tau ntawm kev siv lub tshuab ua haujlwm manually.Zuag qhia tag nrho, kev tswj hwm ntawm CNC-khiav mills thiab lathes zoo ib yam.Raws li nrog CNC mills, tshuab dhos tuaj yeem raug coj los ntawm G-code lossis tus lej cim tshwj xeeb.Txawm li cas los xij, feem ntau CNC tshuab dhos muaj ob axes - X thiab Z.

CNC Milling tshuab

CNC Milling yog cov txheej txheem machining uas siv cov cuab yeej sib hloov ntau lub ntsiab lus kom tshem tawm cov khoom ntawm cov khoom ua haujlwm.CNC mills muaj peev xwm khiav ntawm cov kev pab cuam muaj xws li cov lej-thiab ntawv-raws li kev tshoov siab uas coj cov khoom hla ntau qhov deb.Lub programming ua haujlwm rau lub tshuab zeb tuaj yeem ua raws li Gode lossis qee yam lus tshwj xeeb tsim coj pab pawg, Basic m-cos muaj peb-axis system (X, Y thiab Z), txawm hais tias feem ntau cov mills tshiab tuaj yeem haum peb axes ntxiv.Kev ua haujlwm muaj peev xwm ntawm cov txheej txheem milling muaj xws li lub ntsej muag milling-txiav ntiav, tiaj tiaj thiab tiaj-hauv qab kab noj hniav rau hauv lub workpiece-thiab peripheral milling-txiav cov kab noj hniav sib sib zog nqus, xws li cov qhov thiab cov xov, rau hauv workpiece.

5 Axis machining

Lub 3, 4, los yog 5 axis machining yog txhais hais tias muaj feem xyuam rau tus naj npawb ntawm cov lus qhia nyob rau hauv uas lub cuab tam yuav txav tau, qhov no kuj txiav txim siab lub peev xwm ntawm lub tshuab CNC txav ib tug workpiece thiab ib lub cuab tam.3-axis machining chaw tuaj yeem txav ib feem hauv X thiab Y cov lus qhia thiab cov cuab yeej txav nce thiab nqis raws Z-axis, thaum nyob rau ntawm 5 axis machining chaw, lub cuab yeej tuaj yeem txav mus hla X, Y thiab Z linear axes nrog rau rotates ntawm A thiab B axes, uas ua rau lub cutter tuaj yeem txav mus rau qhov chaw ua haujlwm ntawm txhua qhov kev taw qhia thiab txhua lub kaum ntse ntse.5 axis machining txawv ntawm 5-sided machining.Yog li ntawd, 5 axis CNC machining cov kev pab cuam cia iinfinte possibilities ntawm machined qhov chaw.Hook nto machining, txawv txawv machining, hollow machining, xuas nrig ntaus, oblique txiav, thiab ntau tshwj xeeb prcesses yuav ua tau nrog 5 axis CNC machining kev pab cuam.

Swiss Hom Machining

Swiss hom machining yog hu ua machining los ntawm Swiss hom tshuab dhos los yog Swiss automatic tshuab dhos, nws yog ib tug niaj hnub precision manufacturing uas yuav ua tau heev me me qhov chaw sai thiab meej.

Lub tshuab Swiss ua haujlwm los ntawm kev pub khoom noj khoom haus los ntawm kev qhia bushing, uas khov kho cov khoom siv thaum nws nkag mus rau hauv qhov chaw ntawm lub tshuab.

Piv nrog traidtional automatic lathes Swiss hom lathes yog qhov tshwj xeeb uas muaj peev xwm ua tau me me, qhov tseeb ntawm qhov nrawm nrawm.Kev sib xyaw ua ke ntawm kev ua haujlwm siab thiab siab ntau lawm ua rau Swiss cov cav tov yog ib qho tseem ceeb ntawm cov khoom siv rau cov khw muag khoom uas yuav tsum tsim cov ntim loj ntawm cov khoom me me thiab tsis sib xws nrog cov npoo me me rau qhov yuam kev.

Khoom siv hauv CNC Machining Application

Thaum muaj ntau yam khoom siv uas koj tuaj yeem siv hauv lub tshuab CNC, cov khoom siv feem ntau siv yog:

Aluminium Alloys

● Al 6061-T6

● Al6063-T6

● Al7075-T6

● Al5052

● Al2024

Stainless hlau Alloys:

● Stainless hlau 303/304

● Stainless hlau 316/316L

● Stainless hlau 420

● Stainless hlau 410

● Stainless hlau 416

● Stainless hlau 17-4H

● Stainless hlau 18-8

Yas:

● POM (Delrin), ABS (Acrylonitrile Butadiene Styrene)

● HDPE, Nylon (PA), PLA, PC (Polycarbonate)

● PEEK (Polyether Ether Ketone)

● PMMA (Polymethyl Methacrylate lossis Acrylic)

● PP (Polypropylene)

● PTFE (Polytetrafluoroethylene)

Copper & Brass Alloys:

● Tooj 260

● Tooj 360

● H90, H80, H68, H62

Carbon hlau alloys:

● Hlau 1018, 1024, 1215

● Hlau 4140, 4130

● Steel A36…

Titanium alloys:

● Titanium (Qib 2)

● Titanium (Qib 5)

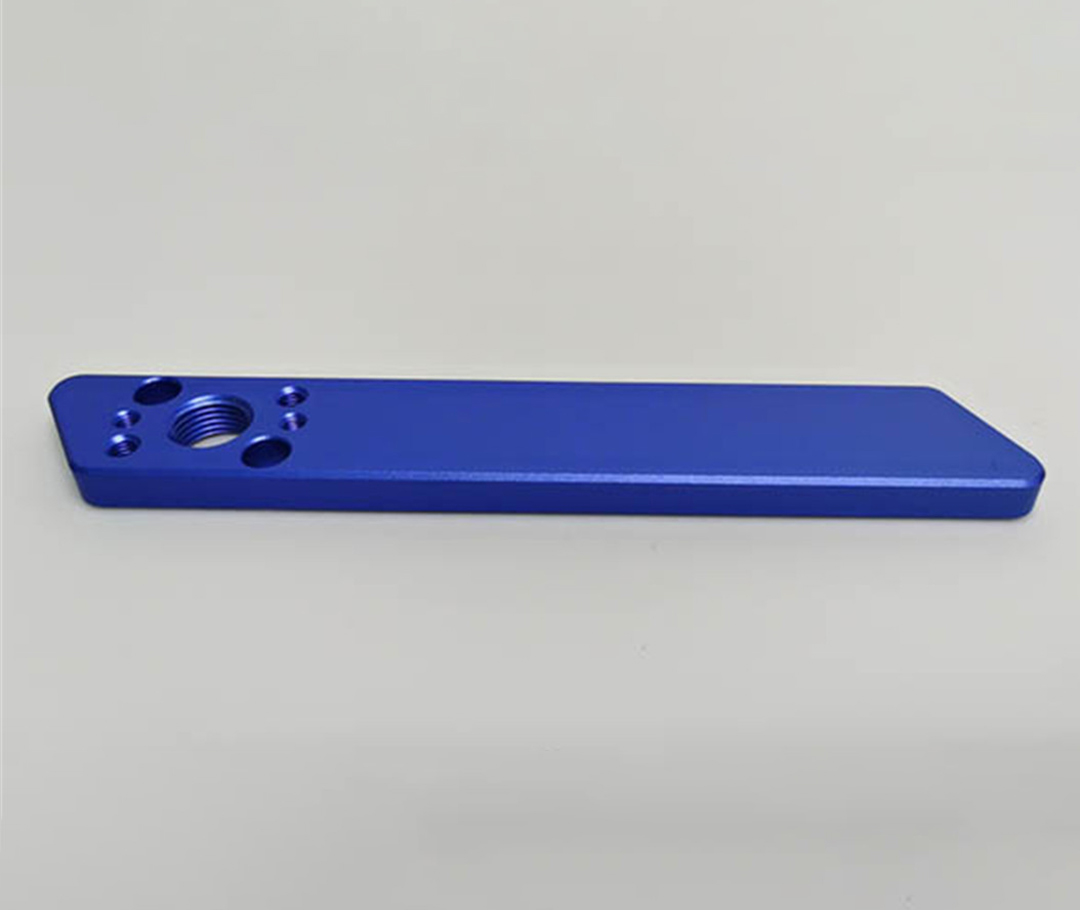

CNC Finishing thiab Post-processing Options

Nto xov yog cov kauj ruam kawg ntawm CNC machining.Kev ua tiav tuaj yeem siv los tshem tawm qhov tsis zoo nkauj, txhim kho cov khoom zoo, muab lub zog ntxiv thiab ua haujlwm, kho hluav taws xob conductivity, thiab ntau ntxiv.

● Raws li Machined

● Anodizing (Hom II & Hom III)

● hmoov txheej

● Electroplating

● Bead blasting

● Tuav

● Passivation

● Chemical Film (Chromate Conversion Txheej)

Saib qee qhov piv txwv ntawm Peb CNC Machinined qhov chaw

Adantages ntawm Ordering CNC Machined Parts los ntawm Star Machining

Rapid Turnaround:Cov lus teb ceev ceev rau RFQ hauv 24 teev.Siv cov tshuab CNC tshiab kawg, Star Machining ua tau zoo heev, nrawm tig qhov nrawm nrawm li 10 hnub.

Precision:Lub Hnub Qub Machining muaj ntau yam kev xaiv kam rau ua raws li ISO 2768 tus qauv thiab tseem nruj dua raws li koj qhov kev thov.

Kev xaiv khoom siv:Xaiv los ntawm ntau dua 30 cov ntaub ntawv hlau thiab yas raws li koj xav tau.

Custom Finishes:Xaiv los ntawm ntau yam o tiav ntawm cov khoom hlau thiab cov khoom yas, ua rau cov qauv tsim tshwj xeeb.

Kev paub:Peb cov kws tshaj lij kev paub dhau los yuav muab cov lus qhia DFM sai rau koj.Lub hnub qub Machining muaj ntau tshaj 15 xyoo ntawm kev tsim khoom.Muaj ntau txhiab lub tuam txhab thiab cov haujlwm uas peb tau ua haujlwm rau ntau yam kev lag luam, ntau tshaj 50 lub teb chaws uas peb xa khoom.

Kev Tswj Xyuas Zoo:Peb lub tuam txhab QA ua haujlwm muaj kev ruaj ntseg zoo.Los ntawm cov khoom mus rau qhov kawg cov khoom xa tuaj peb ua nruj me ntsis soj ntsuam nrog thoob ntiaj teb tus qauv.Qee qhov chaw peb ua tag nrho kev tshuaj xyuas raws li cov neeg siv khoom thov.

Kev xa khoom sai:Tsuas yog rau tus neeg nqa khoom, peb tseem muaj peb tus kheej DHL / UPS tus neeg sawv cev thiab tus neeg xa khoom tuaj yeem xa koj cov khoom nrog xa khoom sai thiab tus nqi zoo.